ZeroLengthImpact3D: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 47: | Line 47: | ||

# This element has been developed on top of the “zeroLengthContact3D”. All the notes available in “zeroLengthContact3D” wiki page would apply to this element as well. It includes the definition of master and slave nodes, the number of degrees of freedom in the domain, etc. Please refer to [[ ZeroLengthContact_Element | “zeroLengthContact3D” ]] for detailed descriptions. | # This element has been developed on top of the “zeroLengthContact3D”. All the notes available in “zeroLengthContact3D” wiki page would apply to this element as well. It includes the definition of master and slave nodes, the number of degrees of freedom in the domain, etc. Please refer to [[ ZeroLengthContact_Element | “zeroLengthContact3D” ]] for detailed descriptions. | ||

# This element adds the capabilities of [[ Impact_Material | “ImpactMaterial” ]] to “zeroLengthContact3D”, without the need for extra nodes and elements in the modeling process. That is the capability of having an | # This element adds the capabilities of [[ Impact_Material | “ImpactMaterial” ]] to “zeroLengthContact3D”, without the need for extra nodes and elements in the modeling process. That is the capability of having an initial gap in the normal direction and also the capability of considering energy dissipation due to impact in the normal direction. | ||

# This element has been employed to model the '''superstructure-abutment interaction in bridges''' at University of Connecticut (UConn) and University of Nevada, Reno (UNR). This element was found to be fast-converging and eliminating the need for many extra elements and nodes in the modeling process. | # This element has been employed to model the '''superstructure-abutment interaction in bridges''' at University of Connecticut (UConn) and University of Nevada, Reno (UNR). This element was found to be fast-converging and eliminating the need for many extra elements and nodes in the modeling process. | ||

Revision as of 12:50, 29 May 2013

- Command_Manual

- Tcl Commands

- Modeling_Commands

- model

- uniaxialMaterial

- ndMaterial

- frictionModel

- section

- geometricTransf

- element

- node

- sp commands

- mp commands

- timeSeries

- pattern

- mass

- block commands

- region

- rayleigh

- Analysis Commands

- Output Commands

- Misc Commands

- DataBase Commands

This command constructs a node-to-node zero-length contact element in 3D space.

| element zeroLengthImpact3D $tag $slaveNode $masterNode $direction $initGap $frictionRatio $Kt $Kn $Kn2 $Delta_y $cohesion |

| $tag | Unique element object tag |

| $slaveNode | Slave node tag |

| $masterNode | Master node tag |

| $direction |

1 if normal vector of master plane points to +X direction 2 if normal vector of master plane points to +Y direction 3 if normal vector of master plane points to +Z direction |

| $initGap | Initial gap between master plane and slave plane |

| $frictionRatio | Friction ratio |

| $Kt | Penalty in tangential directions (parallel to master and slave planes) |

| $Kn | Penalty in normal direction (normal to master and slave planes) |

| $Kn2 | Penalty in normal direction after yielding based on Hertz impact model |

| $Delta_y | Yield deformation based on Hertz impact model |

| $cohesion | Cohesion, if no cohesion, it is zero |

NOTES:

- This element has been developed on top of the “zeroLengthContact3D”. All the notes available in “zeroLengthContact3D” wiki page would apply to this element as well. It includes the definition of master and slave nodes, the number of degrees of freedom in the domain, etc. Please refer to “zeroLengthContact3D” for detailed descriptions.

- This element adds the capabilities of “ImpactMaterial” to “zeroLengthContact3D”, without the need for extra nodes and elements in the modeling process. That is the capability of having an initial gap in the normal direction and also the capability of considering energy dissipation due to impact in the normal direction.

- This element has been employed to model the superstructure-abutment interaction in bridges at University of Connecticut (UConn) and University of Nevada, Reno (UNR). This element was found to be fast-converging and eliminating the need for many extra elements and nodes in the modeling process.

EXAMPLE SCRIPT:

The following zip file contains an example script and the corresponding input cyclic displacement.

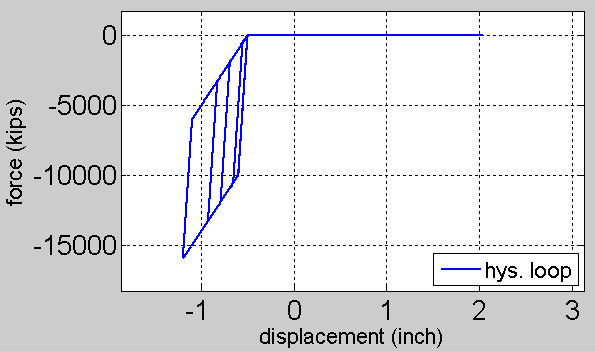

After running the example script, the following hysteresis loop is resulted in normal direction under cyclic excitation:

REFERENCES:

Code Developed by: Dr. Arash E. Zaghi, Majid Cashany, University of Connecticut (UConn)