Fatigue Material: Difference between revisions

No edit summary |

No edit summary |

||

| Line 54: | Line 54: | ||

'''NOTE:''' Here you can find more information of how to create 'damage' recorders: [http://opensees.berkeley.edu/community/viewtopic.php?f=2&t=54193] | '''NOTE:''' Here you can find more information of how to create 'damage' recorders: [http://opensees.berkeley.edu/community/viewtopic.php?f=2&t=54193 link] | ||

Latest revision as of 18:34, 13 July 2012

- Command_Manual

- Tcl Commands

- Modeling_Commands

- model

- uniaxialMaterial

- ndMaterial

- frictionModel

- section

- geometricTransf

- element

- node

- sp commands

- mp commands

- timeSeries

- pattern

- mass

- block commands

- region

- rayleigh

- Analysis Commands

- Output Commands

- Misc Commands

- DataBase Commands

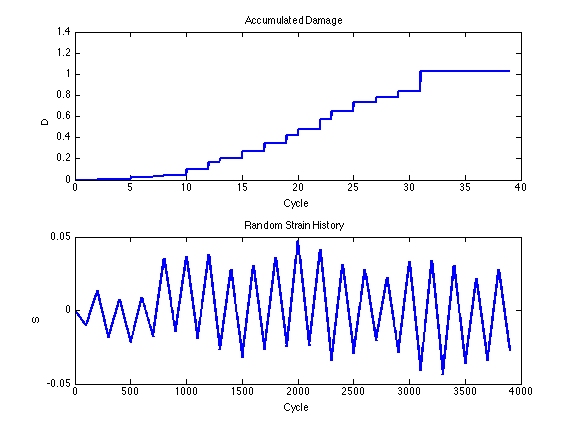

The fatigue material uses a modified rainflow cycle counting algorithm to accumulate damage in a material using Miner’s Rule. Element stress/strain relationships become zero when fatigue life is exhausted.

| uniaxialMaterial Fatigue $matTag $tag <-E0 $E0> <-m $m> <-min $min> <-max $max> |

| $matTag | integer tag identifying material |

| $tag | Unique material object integer tag for the material that is being wrapped |

| $E0 | Value of strain at which one cycle will cause failure (default 0.191) |

| $m | Slope of Coffin-Manson curve in log-log space (default -0.458) |

| $min | Global minimum value for strain or deformation (default -1e16) |

| $max | Global maximum value for strain or deformation (default 1e16) |

Description

This material model accounts for the effects of low cycle fatigue. A modified rainflow cycle counter has been implemented to track strain amplitudes. This cycle counter is used in concert with a linear strain accumulation model (i.e. Miner’s Rule), based on Coffin-Manson log-log relationships describing low cycle fatigue failure. This material wraps around another material and does not influence the stress-strain (or force-deformation) relationship of the parent material.

Once the Fatigue material model reaches a damage level of 1.0, the force (or stress) of the parent material becomes zero (1.0x10-8 times the call to the material). If failure is triggered in compression, the material stress is dropped at the next zero-force crossing (i.e. compression force never drops to zero).

The Fatigue material assumes that each point is the last point of the history, and tracks damage with this assumption. If failure is not triggered, this pseudo-peak is discarded.

The material also has the ability to trigger failure based on a maximum or minimum strain (i.e. not related to fatigue). The default for these values is set to very large numbers.

The default values are calibrated parameters from low cycle fatigue tests of European steel sections Ballio and Castiglioni (1995), for more information about how material was calibrated, the user is directed to Uriz (2005).

Valid recorder objects for the material are ‘stress’,’tangent’, ‘strain’, ‘stressStrain’, and ‘damage’. The stress, strain, and tangent recorder options must be available in the material that you are wrapping.

NOTE: Here you can find more information of how to create 'damage' recorders: link

Example:

Click to Download

References:

Uriz, Patxi (2005) “Towards Earthquake Resistant Design of Concentrically Braced Steel Structures,” Doctoral Dissertation, Structural Engineering, Mechanics, and Materials, Department of Civil and Environmental Engineering, University of California, Berkeley, December 2005

Ballio, G., and Castiglioni, C. A. (1995). "A Unified Approach for the Design of Steel Structures under Low and/or High Cycle Fatigue." Journal of Constructional Steel Research, 34, 75-101.

Code Developed by: Patxi Uriz, Exponent