Maxwell Material: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| (13 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

{{CommandManualMenu}} | {{CommandManualMenu}} | ||

This command is used to construct a Maxwell | This command is used to construct a ViscousDamper material, which represents the [http://en.wikipedia.org/wiki/Maxwell_material Maxwell Model] (linear spring and nonlinear dashpot in series). The ViscousDamper material simulates the hysteretic response of nonlinear viscous dampers. An adaptive iterative algorithm has been implemented and validated to solve numerically the constitutive equations within a nonlinear viscous damper with a high-precision accuracy. | ||

{| | {| | ||

| style="background: | | style="background:lime; color:black; width:800px" | '''uniaxialMaterial ViscousDamper $matTag $K $Cd $alpha <$LGap> < $NM $RelTol $AbsTol $MaxHalf> ''' | ||

|} | |} | ||

| Line 12: | Line 12: | ||

| style="width:150px" | '''$matTag ''' || integer tag identifying material | | style="width:150px" | '''$matTag ''' || integer tag identifying material | ||

|- | |- | ||

| '''$K ''' || Elastic stiffness of linear spring | | '''$K ''' || Elastic stiffness of linear spring to model the axial flexibility of a viscous damper (e.g. combined stiffness of the supporting brace and internal damper portion) | ||

|- | |- | ||

| '''$ | | '''$Cd ''' || Damping coefficient | ||

|- | |- | ||

| '''$ | | '''$alpha ''' || Velocity exponent | ||

|- | |- | ||

| '''$ | | '''$LGap ''' || Gap length to simulate the gap length due to the pin tolerance | ||

|- | |- | ||

| '''$NM ''' || Employed adaptive numerical algorithm (default value NM = 1; 1 = Dormand-Prince54, 2=6th order Adams-Bashforth-Moulton, 3=modified Rosenbrock Triple) | |||

|- | |||

| '''$RelTol ''' || Tolerance for absolute relative error control of the adaptive iterative algorithm (default value 10^-6) | |||

|- | |||

| '''$AbsTol ''' || Tolerance for absolute error control of adaptive iterative algorithm (default value 10^-10) | |||

|- | |||

| '''$MaxHalf ''' || Maximum number of sub-step iterations within an integration step (default value 15) | |||

|- | |||

|} | |} | ||

| Line 29: | Line 37: | ||

| '''''1. Input parameters:''''' | | '''''1. Input parameters:''''' | ||

|- | |- | ||

| Assume a viscous damper with axial stiffness K= | | Assume a viscous damper with axial stiffness K=300.0kN/mm, damping coefficient Cd=280.3kN(s/mm)<sup>0.3</sup>, and exponent a=0.30. | ||

|- | |- | ||

| The input parameters for the material should be as follows: | | The input parameters for the material should be as follows: | ||

| Line 35: | Line 43: | ||

|- | |- | ||

|- | |- | ||

| uniaxialMaterial | | uniaxialMaterial ViscousDamper 1 300 280.3 0.30 | ||

|- | |- | ||

|- | |- | ||

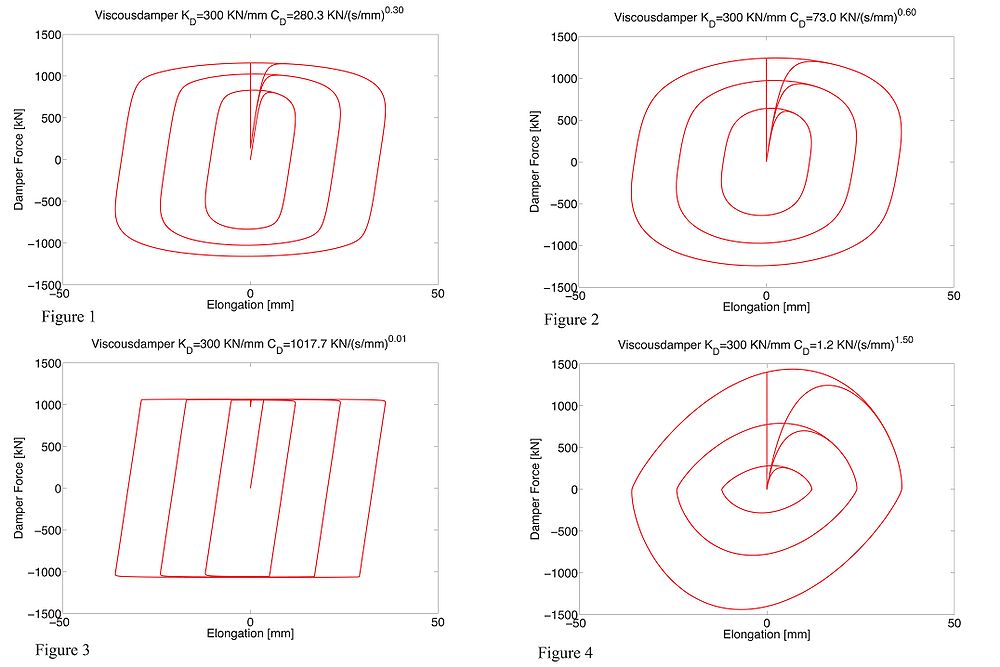

| Using these properties | | Using these properties, Figure 1 shows the hysteretic response of this damper for sinusoidal displacement increments of 12, 24 and 36mm and a frequency f = 0.5Hz. | ||

|- | |- | ||

|The sensitivity of the viscous damper with respect to its | |The sensitivity of the viscous damper with respect to its velocity exponent is shown in Figures 2 to 4 for the following set of parameters: | ||

|- | |- | ||

| [[File: | | [[File:ViscousDamperFig.jpg|1000px|thumb|left| Viscous Damper with various input parameter variations]] | ||

|- | |- | ||

|- | |- | ||

| '''''[http://opensees.berkeley.edu/wiki/index.php/Viscous_Damper_Material 2. Single story single bay frame with viscous damper]''''' | |||

|- | |- | ||

|- | |- | ||

|} | |} | ||

| Line 57: | Line 61: | ||

'''References''': | '''References''': | ||

{| | {| | ||

| style="width:5px" | '''[1]''' || | | style="width:5px" | '''[1]''' || Akcelyan, S., Lignos, D. G., Hikino, T., and Nakashima, M. (2016). “Evaluation of simplified and state-of-the-art analysis procedures for steel frame buildings equipped with supplemental damping devices based on E-Defense full-scale shake table tests.” Journal of Structural Engineering, 142(6), 04016024. [http://ascelibrary.org/doi/ref/10.1061/%28ASCE%29ST.1943-541X.0001474] | ||

|- | |||

| style="width:5px" | '''[2]''' || Oohara, K., and Kasai, K. (2002), “Time-History Analysis Models for Nonlinear Viscous Dampers”, Proc. Structural Engineers World Congress (SEWC), Yokohama, JAPAN, CD-ROM, T2-2-b-3 (in Japanese). | |||

|- | |- | ||

|'''[ | |'''[3]''' || Kasai K, Oohara K. “Algorithm and Computer Code To Simulate Response of Nonlinear Viscous Damper” Passively Controlled Structure Symposium 2001, Yokohama, Japan (in Japanese). | ||

|- | |- | ||

|} | |} | ||

Code Developed by : <span style="color:blue"> | Code Developed and Implemented by : <span style="color:blue"> '''''[http://dimitrios-lignos.research.mcgill.ca/PAkcelyan.html Sarven Akcelyan]''''' & '''''[http://dimitrios-lignos.research.mcgill.ca/PLignos.html Prof. Dimitrios G. Lignos]''''', (McGill University) </span> | ||

Latest revision as of 02:22, 30 September 2016

- Command_Manual

- Tcl Commands

- Modeling_Commands

- model

- uniaxialMaterial

- ndMaterial

- frictionModel

- section

- geometricTransf

- element

- node

- sp commands

- mp commands

- timeSeries

- pattern

- mass

- block commands

- region

- rayleigh

- Analysis Commands

- Output Commands

- Misc Commands

- DataBase Commands

This command is used to construct a ViscousDamper material, which represents the Maxwell Model (linear spring and nonlinear dashpot in series). The ViscousDamper material simulates the hysteretic response of nonlinear viscous dampers. An adaptive iterative algorithm has been implemented and validated to solve numerically the constitutive equations within a nonlinear viscous damper with a high-precision accuracy.

| uniaxialMaterial ViscousDamper $matTag $K $Cd $alpha <$LGap> < $NM $RelTol $AbsTol $MaxHalf> |

| $matTag | integer tag identifying material |

| $K | Elastic stiffness of linear spring to model the axial flexibility of a viscous damper (e.g. combined stiffness of the supporting brace and internal damper portion) |

| $Cd | Damping coefficient |

| $alpha | Velocity exponent |

| $LGap | Gap length to simulate the gap length due to the pin tolerance |

| $NM | Employed adaptive numerical algorithm (default value NM = 1; 1 = Dormand-Prince54, 2=6th order Adams-Bashforth-Moulton, 3=modified Rosenbrock Triple) |

| $RelTol | Tolerance for absolute relative error control of the adaptive iterative algorithm (default value 10^-6) |

| $AbsTol | Tolerance for absolute error control of adaptive iterative algorithm (default value 10^-10) |

| $MaxHalf | Maximum number of sub-step iterations within an integration step (default value 15) |

Examples:

| 1. Input parameters: |

| Assume a viscous damper with axial stiffness K=300.0kN/mm, damping coefficient Cd=280.3kN(s/mm)0.3, and exponent a=0.30. |

| The input parameters for the material should be as follows: |

| uniaxialMaterial ViscousDamper 1 300 280.3 0.30 |

| Using these properties, Figure 1 shows the hysteretic response of this damper for sinusoidal displacement increments of 12, 24 and 36mm and a frequency f = 0.5Hz. |

| The sensitivity of the viscous damper with respect to its velocity exponent is shown in Figures 2 to 4 for the following set of parameters: |

|

| 2. Single story single bay frame with viscous damper |

References:

| [1] | Akcelyan, S., Lignos, D. G., Hikino, T., and Nakashima, M. (2016). “Evaluation of simplified and state-of-the-art analysis procedures for steel frame buildings equipped with supplemental damping devices based on E-Defense full-scale shake table tests.” Journal of Structural Engineering, 142(6), 04016024. [1] |

| [2] | Oohara, K., and Kasai, K. (2002), “Time-History Analysis Models for Nonlinear Viscous Dampers”, Proc. Structural Engineers World Congress (SEWC), Yokohama, JAPAN, CD-ROM, T2-2-b-3 (in Japanese). |

| [3] | Kasai K, Oohara K. “Algorithm and Computer Code To Simulate Response of Nonlinear Viscous Damper” Passively Controlled Structure Symposium 2001, Yokohama, Japan (in Japanese). |

Code Developed and Implemented by : Sarven Akcelyan & Prof. Dimitrios G. Lignos, (McGill University)